How Welding Inspection Service can Save You Time, Stress, and Money.

Wiki Article

The Definitive Guide to Industrial Welding Inspection

Table of ContentsExcitement About Industrial Welding InspectionSome Known Details About Industrial Welding Inspection How Industrial Welding Inspection can Save You Time, Stress, and Money.More About Welding Inspection ServiceGetting The Industrial Welding Inspection To WorkThe Greatest Guide To Industrial Welding Inspection

Below are several of the examinations that are performed at fabrication stores to ensure weld high quality. Visual Weld or Construction Evaluation It is very important to collaborate with a welding and also construction shop that performs visual weld inspections. Throughout a visual weld inspection, business will examine materials before starting the weld, continuously examine the top quality of the weld and products throughout the welding, evaluate the end product when the weld is finished, and also take care of any concerns that the end product may have.

Aesthetic evaluation of the finished bonded product will generally include welders checking to see to it that the typical weld faults are not present in the weld, checking the coating as well as shape, validating that the product dimension matches that of the prints, as well as checking to make sure that the weld is lined up with welding criteria.

The Basic Principles Of Welding Inspection Service

Talking with prospective welding and also fabrication shops will certainly offer you a feeling of whether they really appreciate what they do and also the quality of their job. Call a Reliable Top Quality Welding & Construction Shop Near You If you remain in search of a quality welding and also manufacture store in the Everett location, look no more! Eckstrom Industries was established in 1930 and has actually been servicing the higher Seattle area because.Aesthetic examinations, or Visual Screening, is the most well understood and also fundamental method of evaluation. Aesthetic evaluation entails looking over a tool utilizing the nude eye. The inspector is looking for any type of indicators of problems or flaws. Visual Evaluation requires no tools other than an experienced assessor with an eager eye.

Aesthetic Evaluation little to no innovation contrasted to various other kinds of evaluations. Visual Assessment is straightforward contrasted to other methods, and is much even more price reliable for smaller sized spending plans.

The Ultimate Guide To Welding Inspection Service

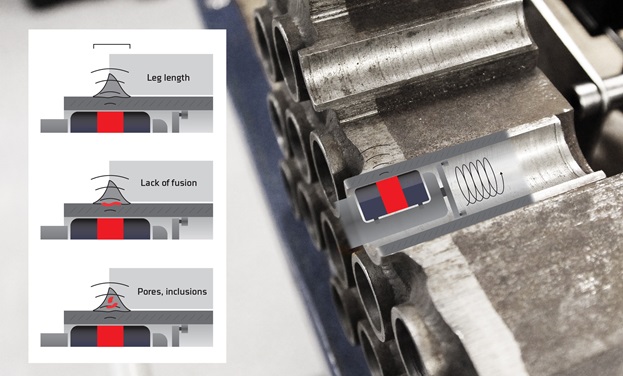

Materials What are welding inspection and also testing? Welding inspection is to examine or understand characteristics a weld has and to inspect gaps in the weld. The size of a weld is really essential as its toughness and also efficiency can be determined. It is good to know the efficiency of a weld and to recognize if it might or might not endure stresses used during service.

Suspensions are recognized as welding problems, and they cause premature weld failing because of included stress focus or decrease of stamina within the welded element. Welding Inspection Service. Assessing the high quality of a weld, there have to be some criteria to which the weld qualities can be contrasted. There are stages some weld gaps can be accepted depending upon the appropriate top quality for its intended application.

Welding Inspection Service for Beginners

It is also suggested to determine the levels of welds suspensions if they can be approved. It is very important to choose as well as follow a welding requirement that is used to a certain application with industry and also know if the designated objectives are met. The acceptance criteria high quality of welding can be stemmed can be gotten from a number of sources (Industrial Welding Inspection).There websites are varieties of training courses available worldwide, but the most preferred program used in the U.S.A. is administered by the American welding society (AWS). What are the Weld evaluation strategies The following stated below are various approaches of inspecting welds; visual examination is most typical, most convenient and the least costly see this website technique of evaluating a weld.

these examination techniques are used to identify great splits, porosity, joints, and also other surface-breaking welding interruptions. Surface crack detection can be accomplished in 2 methods; liquid penetrant assessment or magnetic particle examination. these methods are referred to as They are executed to examine the high quality as well as suspensions of the weld without destroying the welded component.

Excitement About Industrial Welding Inspection

It is performed in order to examine the mechanical and physical characteristics of the weld. Destructive weld screening is additionally done to inspect the top quality of welds. this is among the most successful welding top quality inspection. It needs to want the analysis of full weld high quality requirement as well as acceptance requirements.Welding is a bonding together or coalescence of two comparable or different steel/ steel materials attaining a strength equal to or stronger than the steel base metal. In a building structure, it offers links of steel light beams, columns and also steel plates reinforce the location required for solution. The welding is done in the fabrication store and also or in the area - Welding Inspection Service.

Check the steel material mill certs, filler steel and equipment setups per welding treatment requirements. Steel is the architectural stability and honesty of the building. If welding is refrained from doing by code or treatment it can cause malfunctioning job which would certainly lead to the elimination of weld locations by grinding as well as re-welding.

Welding Inspection Service Can Be Fun For Anyone

At least, the customer may experience a scenario where money can be conserved by making corrections to a pipeline that was identified in advance if an educated SWI was a part of construction. What does a common day or job resemble go to my blog for you? A common day for one task includes: Lead daily/weekly manufacturing conferences with the professionals to review project development and also any kind of issues.Review daily weld and building reports from inspectors. Testimonial bonded procedures and select the applicable procedure for each project/situation.

Report this wiki page